Menu

Close

Foundry

> Applications > Foundry

Are You Looking For A Solution?

Bomaksan Clean Air Experts are here for you. Fill the request form now, get one step closer to the solution.

Case Studies

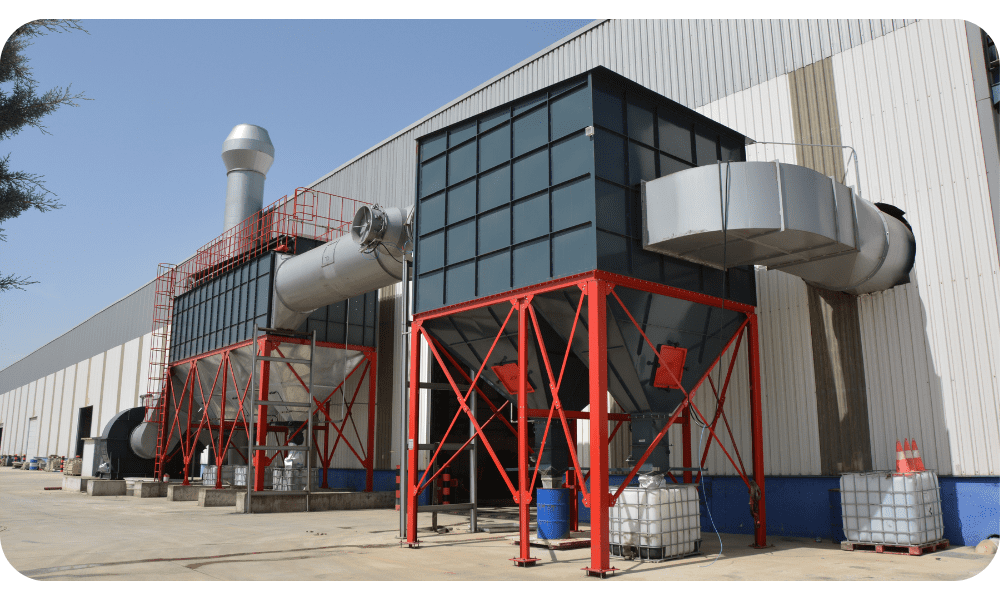

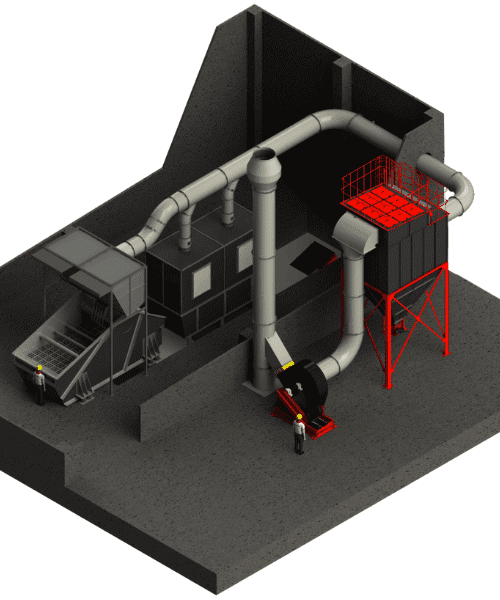

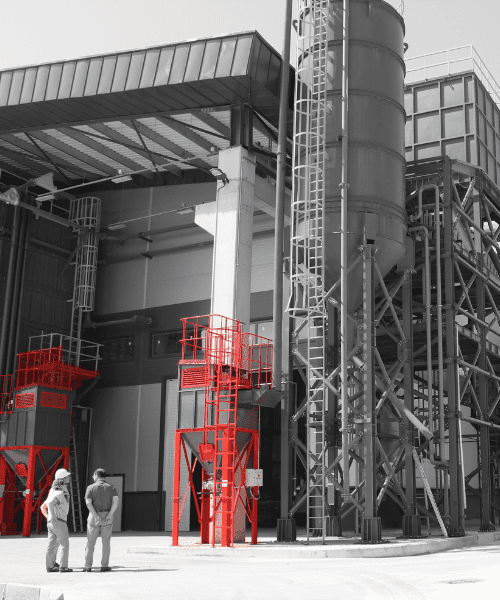

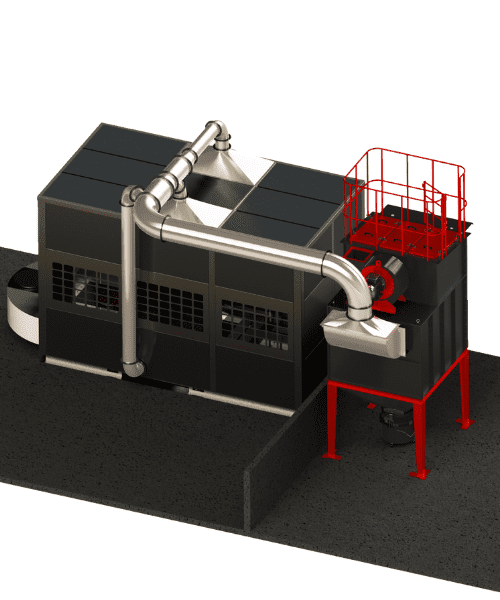

Dust Collectors for Foundry

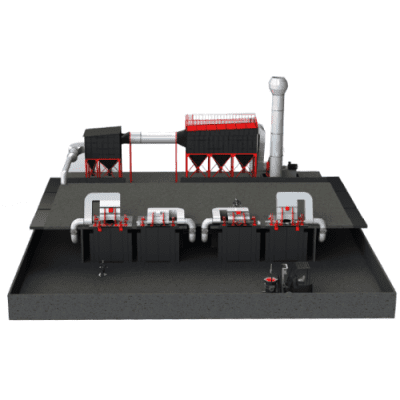

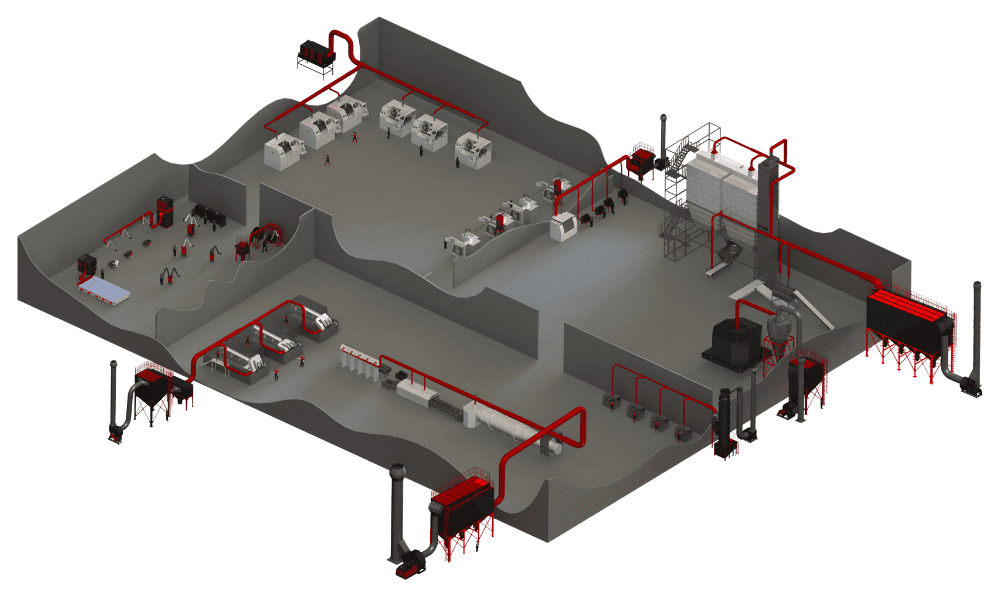

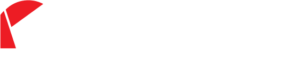

Bomaksan provides all in one Dust Collection and Fume Extraction Solution for Metal Industries.

Bomaksan, which is one of the first companies to come to mind when it comes to foundry ventilation and dust collection systems, is preferred by dozens of companies thanks to its manufacturing and design experience of more than 35 years. Bomaksan is one of the rare companies in its sector that can perform the Project Design, Manufacturing and Project Implementation stages alone, with its expert engineers and technicians during the establishment of foundries – or improvement of an existing dust collection system.

So, in which processes do foundries need a dust collection system

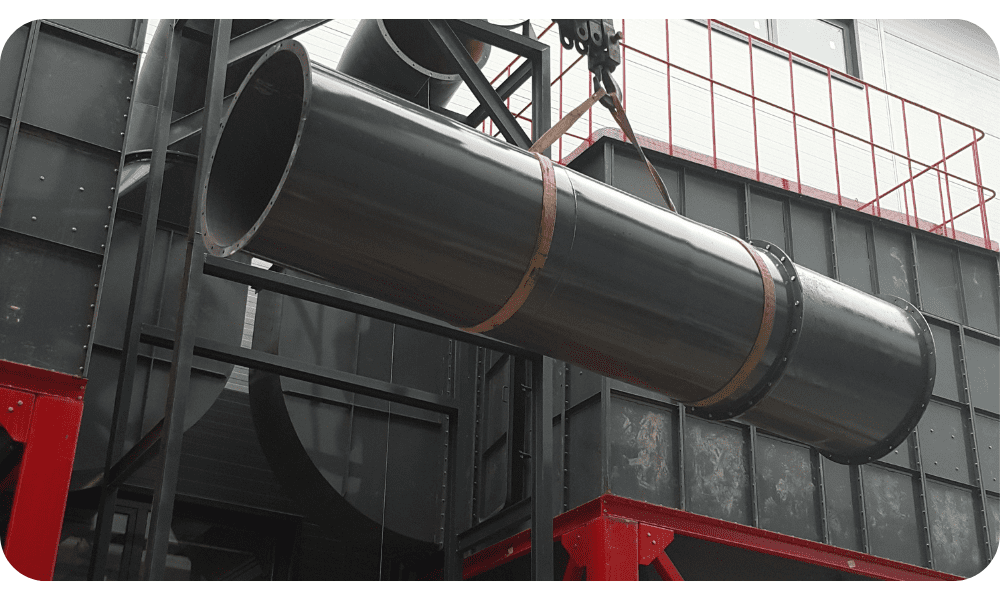

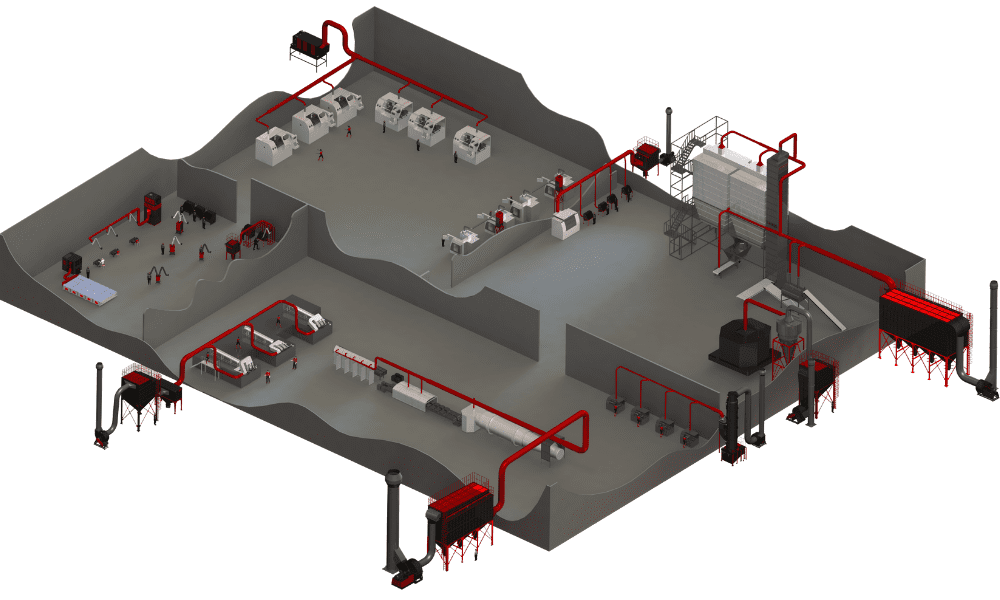

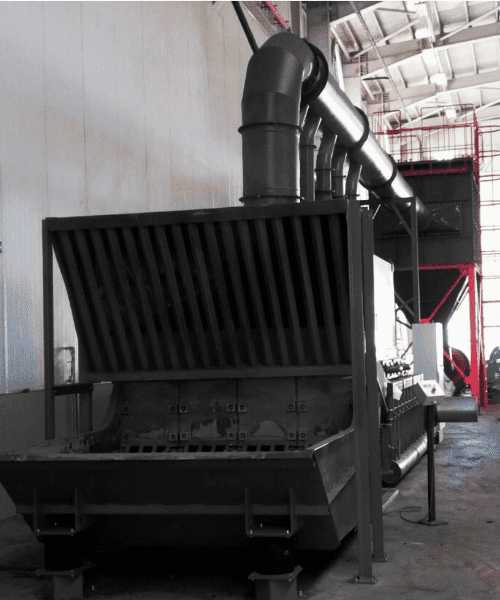

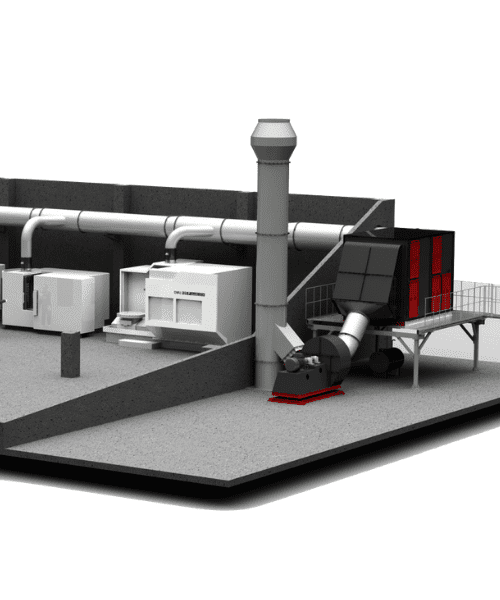

1. COLLECTING DUST AND FUME FROM MELTING FURNACES

Dust and fume extraction and filtration systems in induction furnaces, pouring and cooling lines are very important for the following

– Efficiency

– Occupational health and safety

– Indoor air quality & Legal regulations

– Sustainability & Environment

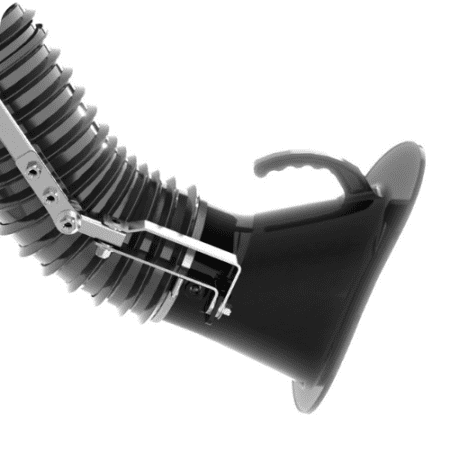

Bomaksan works closely with furnace manufacturers to provide the best solution for melting section dust collection and fume extraction systems. Dust and fume extraction from induction furnaces can be performed by hydraulic hoods produced by furnace manufacturers, or by custom-made hoods designed according to the charging method.

1.A. WHY DO YOU NEED A DUST COLLECTION SYSTEM IN MELTING FURNACES?

Dust and fume released from melting furnaces and casting lines are very harmful to human health and must be collected and filtered properly. It is known that small particles released by molten metals cause several severe diseases, especially upper respiratory tract diseases. Clean working environments ensure high employee productivity and minimize occupational accidents. In many countries, it is required by law to make dust and fume extraction systems and filters for melting furnaces.

The operating principles of melting furnaces may differ from process to process. Bomaksan who has very good knowledge about those systems offers a solution by designing the most energy-efficient dust collection system for you.

2. DUST AND FUME COLLECTING FROM THE SAND PREPARATION PLANT

Dust and fume extraction from Sand Preparation Facilities is very important for the following reasons;

– Saving on the consumption of additives such as resin

– Ability to provide high surface quality in the finished product

– Safer and healthier working environment thanks to the improvement of indoor air quality

– Dust-free environments are safer environments in terms of occupational health and safety. It minimizes health risks caused by both malfunctions caused by the damage caused by dust to electronic components and impairment of indoor air quality.

– Dust collection systems ensure that the released dust is disposed of in a controlled manner. In applications without a dust collection system, dust spreads to the environment uncontrolled by air, and this causes many environmental damages, especially air pollution.

As Bomaksan, we work closely with many sand preparation plant manufacturers to produce the most suitable filtration system for you.

2.A. WHY DO YOU NEED A DUST COLLECTION SYSTEM FOR SAND PREPARATION?

None of the process owners in a foundry wants dust in its molds. The main reason for this is that the dust melts on the surface, causing poor surface quality.

Unwanted and uncollected dust makes it difficult to bind recycled sand and additives such as resin. In order for this sand and resin to bond, dust must be removed from the system. Otherwise, the use of additives increases.

Unwanted dust remaining in the molds burn during casting. These burnt powders create gaps on the surface of the finished product and cause the surface quality to deteriorate.

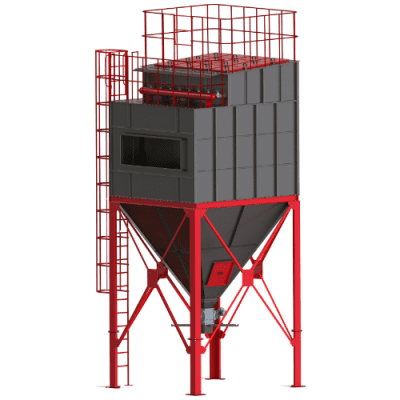

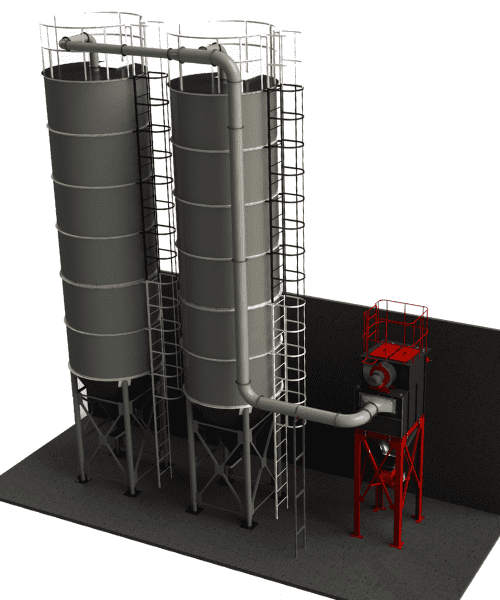

3. DUST AND FUME COLLECTING FROM SILOS

Excessive dust evacuation from silos is very important for the following reasons;

– Saving on the consumption of additives such as resin

– Ability to provide high surface quality in the finished product

– Safer and healthier working environment thanks to the improvement of indoor air quality

– Dust-free environments are safer environments in terms of occupational health and safety. It minimizes health risks caused by both malfunctions caused by the damage caused by dust to electronic components and impairment of indoor air quality.

– Dust collection systems ensure that the released dust is disposed of in a controlled manner. In applications without a dust collection system, dust spreads to the environment uncontrolled by air, and this causes many environmental damages, especially air pollution.

3.A.WHY DO YOU NEED A DUST COLLECTING SYSTEM IN SAND SILOS?

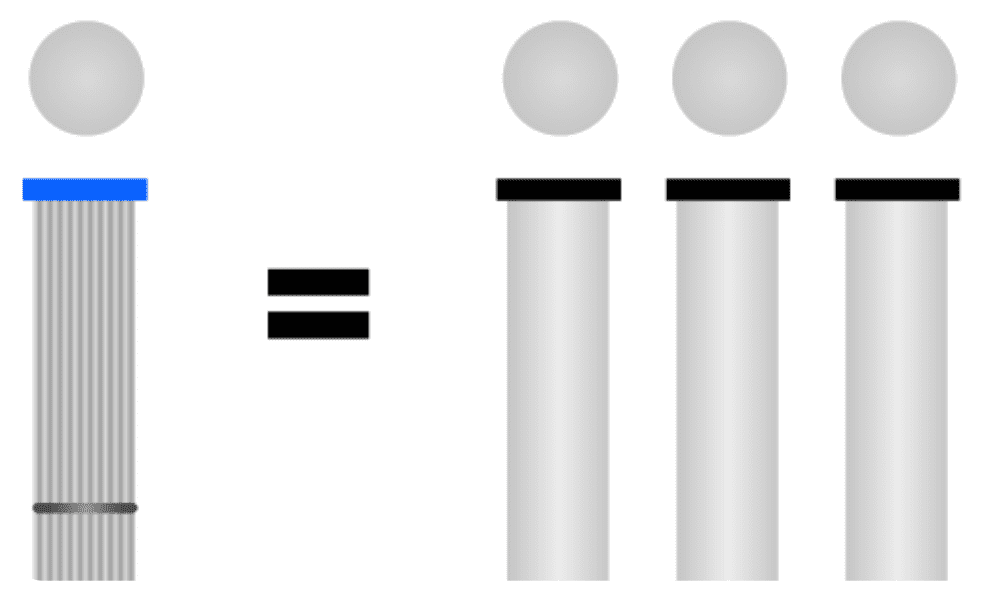

When the sand is sent to the silos, dust is released due to the movement of the sand. The main reason why dust is not desired to be in silos is that the dust makes it difficult to bind the sand and the resin, and more resin has to be used to bind the same amount of sand. Silo filters collect unwanted dust from inside the silo and make the sand as dust-free as possible.

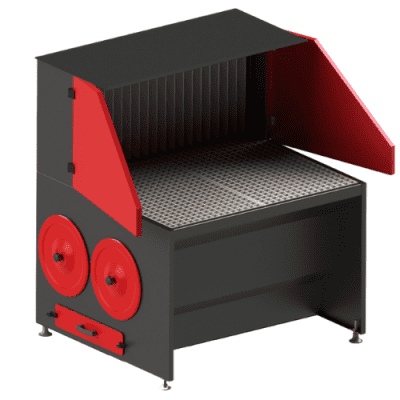

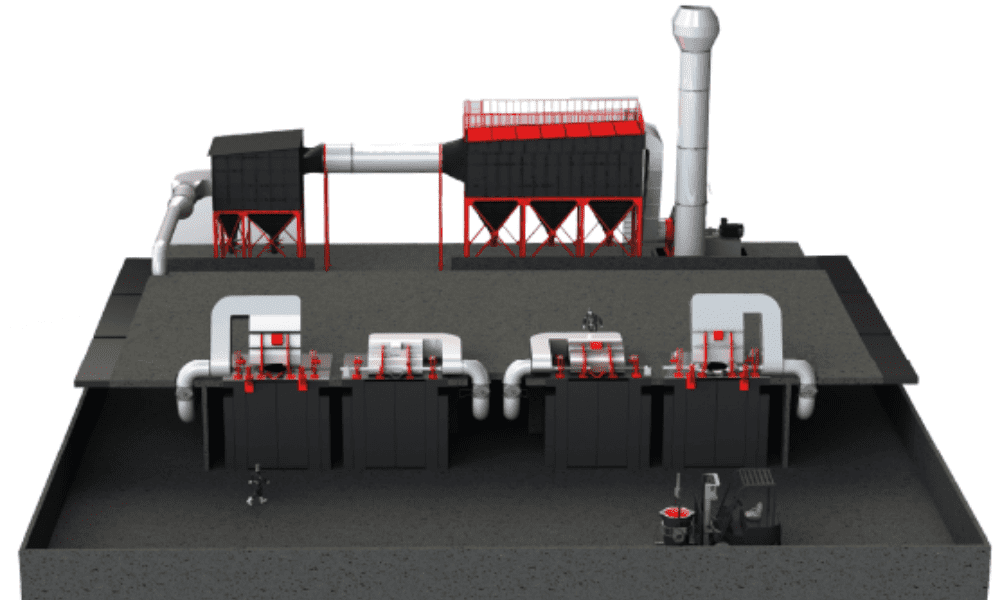

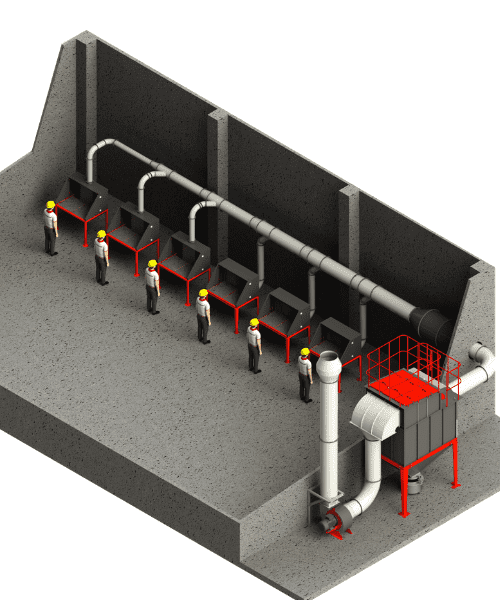

4. DUST AND FUME COLLECTING IN GRINDING AND SANDBLASTING

The suction of the dust released during grinding and sandblasting is very important for the following reasons;

– Saving on the consumption of additives such as resin

– Ability to provide high surface quality in the finished product

– Safer and healthier working environment thanks to the improvement of indoor air quality

– Dust-free environments are safer environments in terms of occupational health and safety. It minimizes health risks caused by both malfunctions caused by the damage caused by dust to electronic components and impairment of indoor air quality.

– Dust collection systems ensure that the released dust is disposed of in a controlled manner. In applications without a dust collection system, dust spreads to the environment uncontrolled by air, and this causes many environmental damages, especially air pollution.

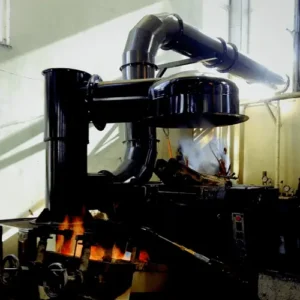

A lot of dust and fume is generated when grinding parts of all sizes. This dust and fumes must be extracted and collected efficiently to keep your work environment healthy and safe.

4.A. WHY DO YOU NEED A DUST COLLECTING SYSTEM FOR GRINDING AND SANDBLASTING?

The main purpose of grinding and sandblasting is to increase the surface quality of the cast part. In order to achieve this goal, people (or robots) clean the unwanted small parts on the cast parts from the surface. This cleaning process creates intense dust and fume. This dust and fume must be collected and filtered in order to prevent them from sticking on the cast part and spoiling the surface quality.

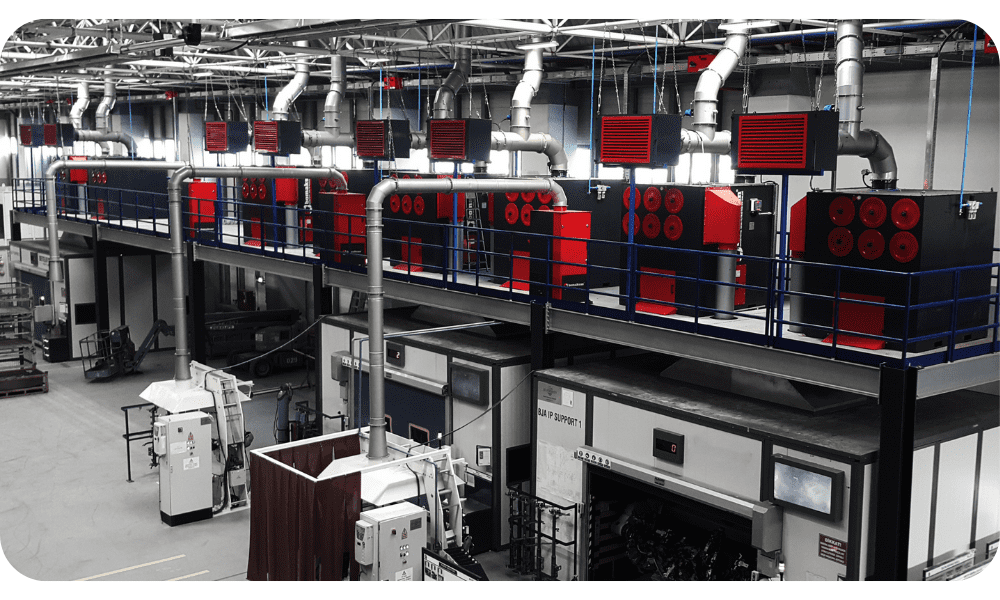

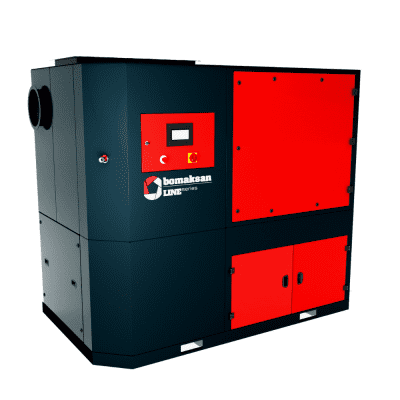

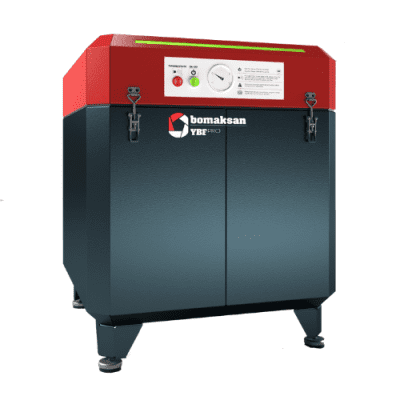

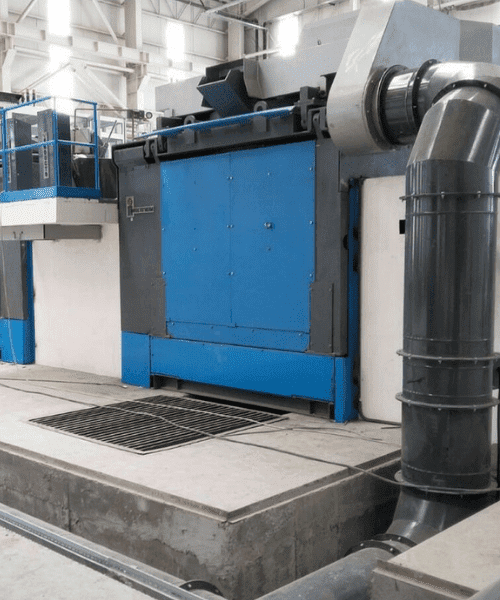

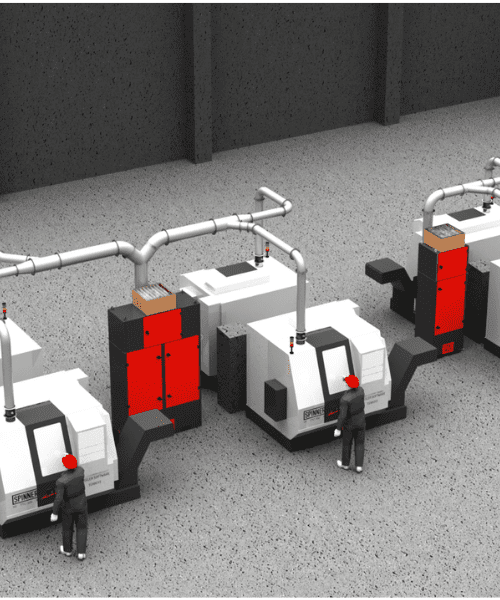

5. OIL MIST COLLECTION IN CNC PROCESSING WORKSHOPS

The extraction of the oil mist released during the CNC process is due to the following reasons.

– Sustainability of the CNC machine

– Safer and healthier working environment thanks to the improvement of indoor air quality

– Dust-free environments are safer environments in terms of occupational health and safety. It minimizes health risks caused by both malfunctions caused by the damage caused by dust to electronic components and impairment of indoor air quality.

– Dust collection systems ensure that the released dust is disposed of in a controlled manner. In applications without a dust collection system, dust spreads to the environment uncontrolled by air, and this causes many environmental damages, especially air pollution.

During CNC Machining, usually, oil, emulsions, or water is used. Due to the high temperature at the contact surface between the shaft and the metal, these fluids evaporate. This evaporated steam is often referred to as oil mist and must be removed and filtered to keep machine parts clean.

5.A. WHY DO YOU NEED OIL MIST FILTER SYSTEM IN CNC PROCESSING WORKSHOPS?

Mist is defined as liquid droplets smaller than 20 microns. These droplets are usually produced by CNC Machines in Foundries. The main purpose of oil mist collection and filtering is to provide a safer and healthier working environment. However, the benefits of collecting oil mist are not limited to safety concerns. Oil mist can damage the interior of your CNC Machines due to their chemical structure. In other words, if you install oil mist collectors on your CNC Machines, you will encounter less downtime and maintenance problems.

WHY BOMAKSAN?

Always With You On Your Way Of Excellence

As Bomaksan, we are aware of your desire to do your job perfectly. Excellence means both producing the best quality product, meeting the quality and deadline expectations of your customers and even exceeding them, creating a healthy and safe working environment and producing without harming the environment.

This is why your investment in Dedusting Systems and Clean Air is actually a direct investment you make to perfect your business.

- Reliable Partner With 35 Years Of Experience!

- ECO-Friendly Engineering Solutions.

- Solutions For Safe Working Environments

- Durable & Sustainable Solutions

Consult Our Clean Air Experts For A More Perfect Production Experience

You can leave your contact information for our Clean Air Experts to provide you with the best support.

You can leave your contact information for our Clean Air Experts to provide you with the best support.

We will try to answer you as soon as possible. In some cases, the response time may be 48 hours.

As a company, we know what we want and since we go with those demands, our supply-demand balance is well maintained. In this respect, Bomaksan is a signature brand. We found answers to all of our problems with need-oriented solutions and alternative approaches. Our satisfaction is always at the top as they do not compromise on fast service and product quality!

Mert EryılmazNETZSCH - Technical Manager

A brand that always meets our expectations with its product quality. It has always been able to please us with the feedback and reactions towards our requests. Its place in the sector is always special with its engineering services and solution-oriented working principles!

Hakan KaplanTrakya Döküm - Assistant Business Engineer

Communication and service quality is at the highest level in Bomaksan. Always a reliable and responsible company!

Yasin TeberLindsay Corporation - Maintanence Technician

We would like to thank Bomaksan for not having any difficulties in communication with its timely service policy. We find answers to all our needs domestically, with the work they do globally!

Hüseyin MetinoğluAlbaksan A.Ş - Production Manager

Bomaksan succeeded in making a difference in the sector with its equipment and product quality. We have always received the best service with their quick reactions to our demands. Fast, reliable and solution oriented.

Orhan KuzubaşPulver Kimya

Bomaksan Dust Collection. It is an expert brand that has entered the production of Gas Treatment and Filtration devices and has managed to make a name for itself in the sector in a short time.

E-Newsletter Subscription

© 2017 - 2022 Bomaksan Industrial Air Filtration Systems. All Rights Reserved.